Engineering Research Institute Ventspils International Radio Astronomy Centre (ERI VIRAC) has implemented a research project "H2-Compression" funded by the European Regional Development Fund

The Ventspils International Radio Astronomy Centre (VIRAC) concluded a significant applied research project on November 30. The project was implemented over nearly three years, with four organizations – the main partner was Ventspils University of Applied Sciences, and as co-partners were "LATVO," the State Scientific Institute - derived public person “Institute of Physical Energetics”, the foundation “Ventspils University of Applied Sciences Development Fund”. On the project were fourteen members of the team, consisting of scientific technical workers, researchers, and students.

The Applied Research Project "Development of Hydrogen Hydraulic Compression Technology for Hydrogen Fueling Stations (H2-Compression)" was implemented under the European Regional Development Fund (ERDF) Operational Programme "Growth and Employment"

More and more countries and companies are competing intensively for leadership in clean hydrogen technologies. More than 30 countries have now developed or are preparing hydrogen strategies, reflecting the growing interest in developing the hydrogen industry. It is clear that hydrogen has the potential to make a significant contribution to addressing three key challenges for energy use: sustainable economic development of the European Union, reducing greenhouse gas emissions and limiting air pollution.

In recent years, the use of hydrogen energy in transport and the concept of a hydrogen economy has gained new and strong political support. At the same time, rapidly advancing technologies have created the opportunity to use hydrogen as a driving force for a future carbon-neutral energy system. This initiative is driven by the desire for energy security and independence. The European Union has set an ambitious target of becoming the first climate neutral continent by 2050, in line with the European Commission's guidelines.

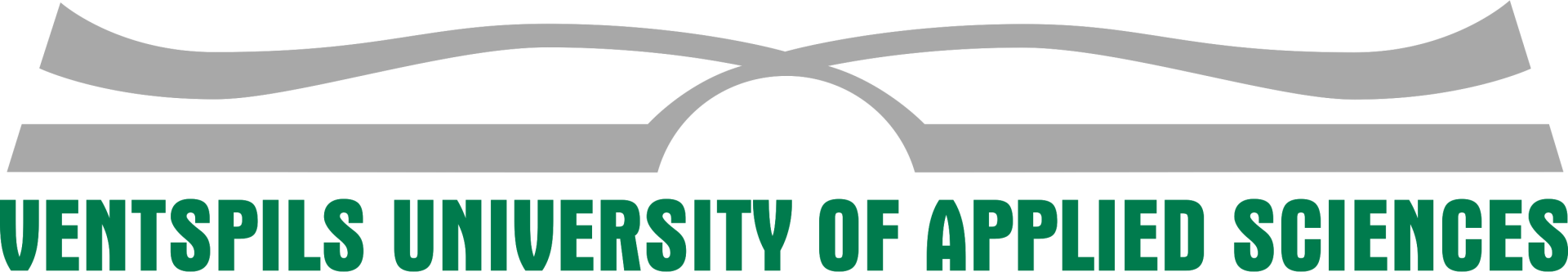

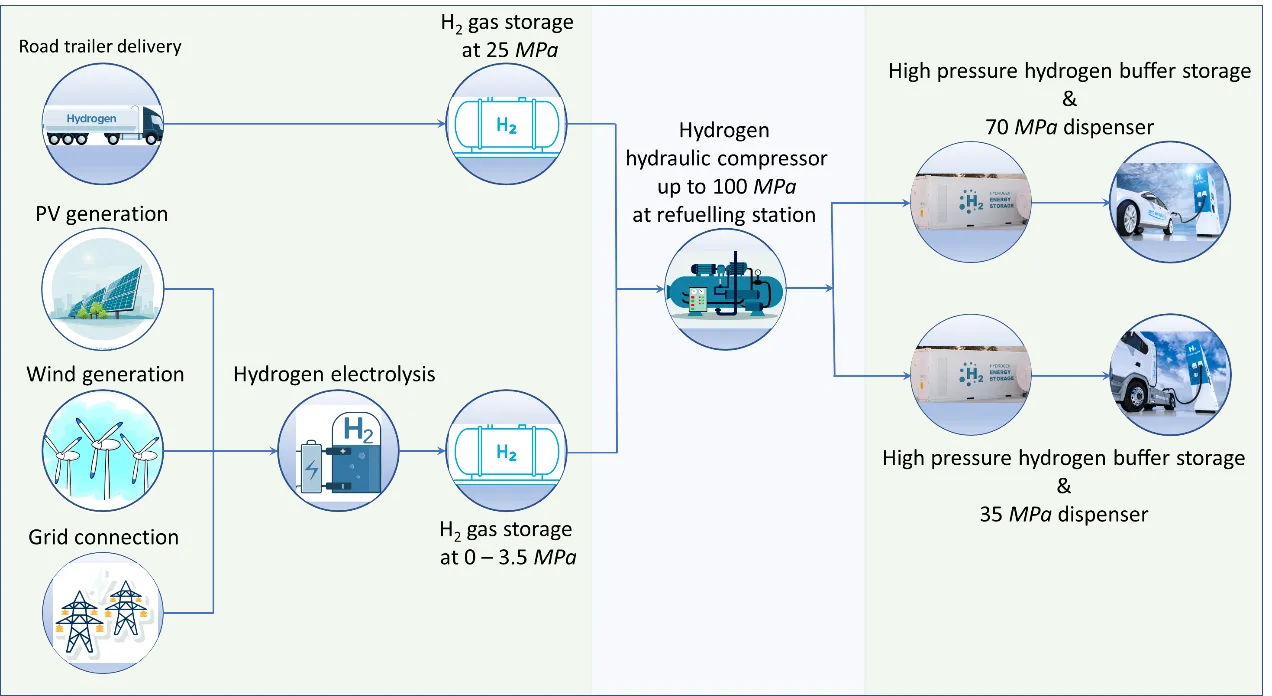

The aim of the research project was to acquire new knowledge and skills to develop an innovative technological solution to compress hydrogen gas. In this system, low-pressure hydrogen gas is compressed by gradually injecting it into vertically positioned compression cylinders and compressing it with a liquid using a high-pressure hydraulic pump. The proposed hydrogen hydraulic compression technology is intended as a compressor booster at a petrol filling station. This station can either receive the hydrogen delivered by truck tanks or produce a limited amount of hydrogen on site by water electrolysis. The uniqueness of this solution is that it is adaptable to varying hydrogen injection pressure parameters and allows the hydrogen storage process in the high-pressure tank to be stabilized.

The project successfully achieved all its objectives, which included:

- Analysis of existing technologies and investigation of hydrogen hydraulic compression problems;

- Development of a reliable numerical model of the hydrogen compression process with a liquid piston, analysis of the thermodynamic parameters of the system to be developed and the temperature variation during gas compression in the proposed solution;

- Selection of a working fluid compatible with hydrogen gas, suitable for use in compression;

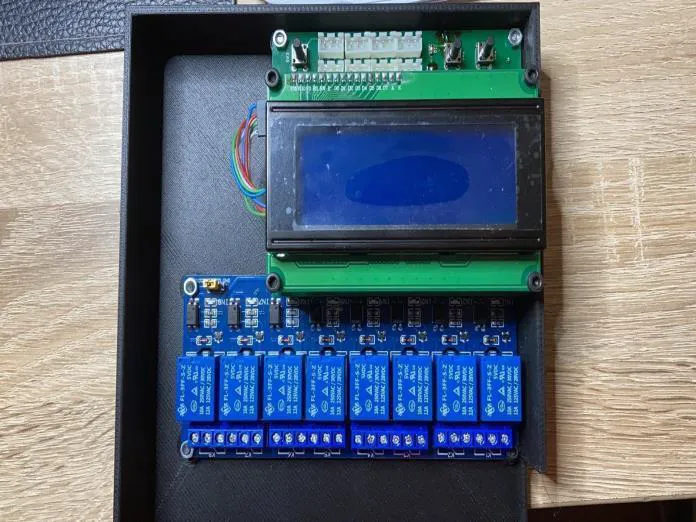

- Development of a set of algorithms for the control of compression processes in a hydrogen compression system.

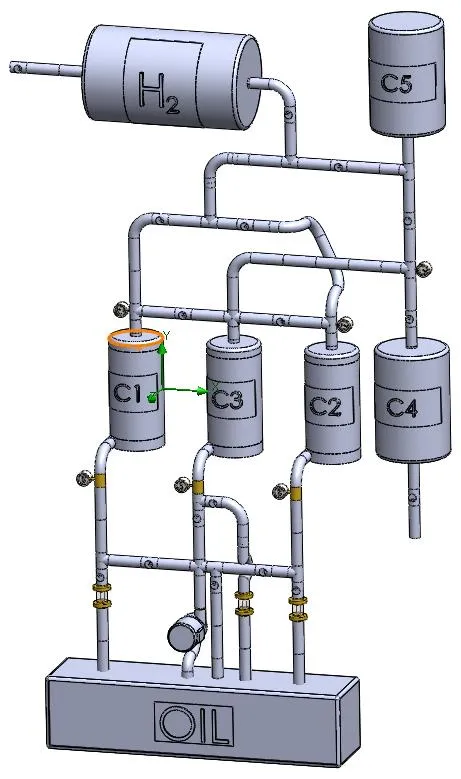

- Development of a new compression chamber geometry technology to reduce gas temperature and foaming inside the vessel by filling it with a fluid under high pressure;

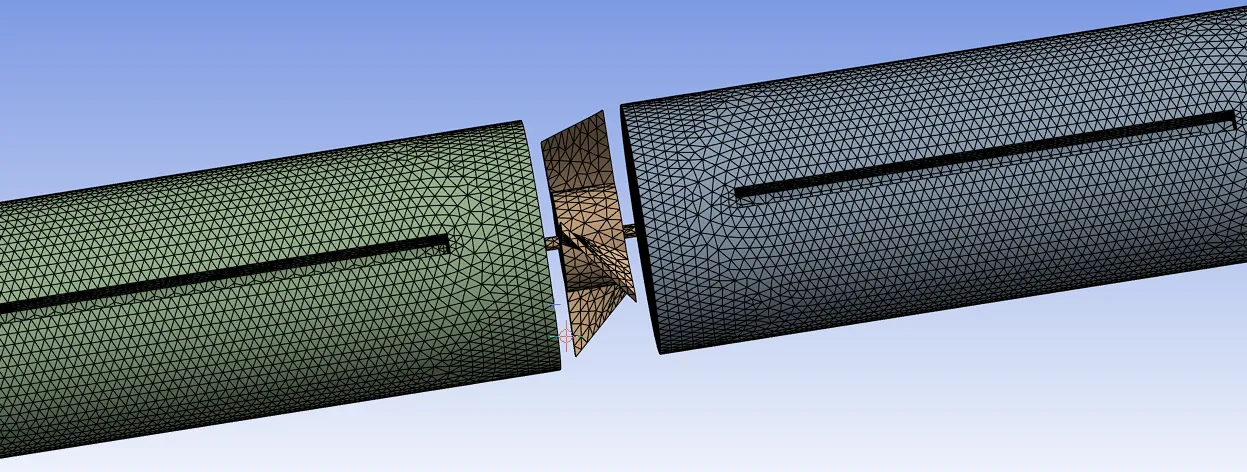

- The development of numerical models of the working fluid flow in the compression chamber;

- Development of numerical models and calibration methodology for the digital flow meter;

- Estimation of the energy consumption for compressing a given volume of gas.

- Analysis of suitable materials for compressors and high pressure hydrogen storage tanks capable of withstanding pressures up to 100 MPa;

- Preparation of documentation for patenting of technical solutions;

- Preparation of project results for publication in scientific journals and for presentation at conferences.

- Selection of industrial partners and adaptation of the technical parameters of the developed system to the needs of the users.

The project results in two new innovative hydrogen compression technologies for use in fuel filling stations for hydrogen-fuelled urban transport. The technical solutions developed within the project could be of particular interest for further commercialisation with companies involved in hydrogen compression and the development of the hydrogen industry. The proposed concept is particularly appealing when combined with the use of Green hydrogen produced by electrolysis, wind turbines, solar cells or the electrical power network.This project, originally conceived as an industrial research activity, has provided all team members involved with new knowledge and skills to create innovative technological solutions.

The results of the project have significantly broadened the understanding of the hydrogen economy and more clearly identified its future prospects. Thanks to this project, the research team joined the Latvian Hydrogen Association. During the last year and a half, we regularly informed the association about the ongoing research, shared the project results, sought potential partners for further cooperation, and kept up-to-date with the latest information in the field of hydrogen energy.

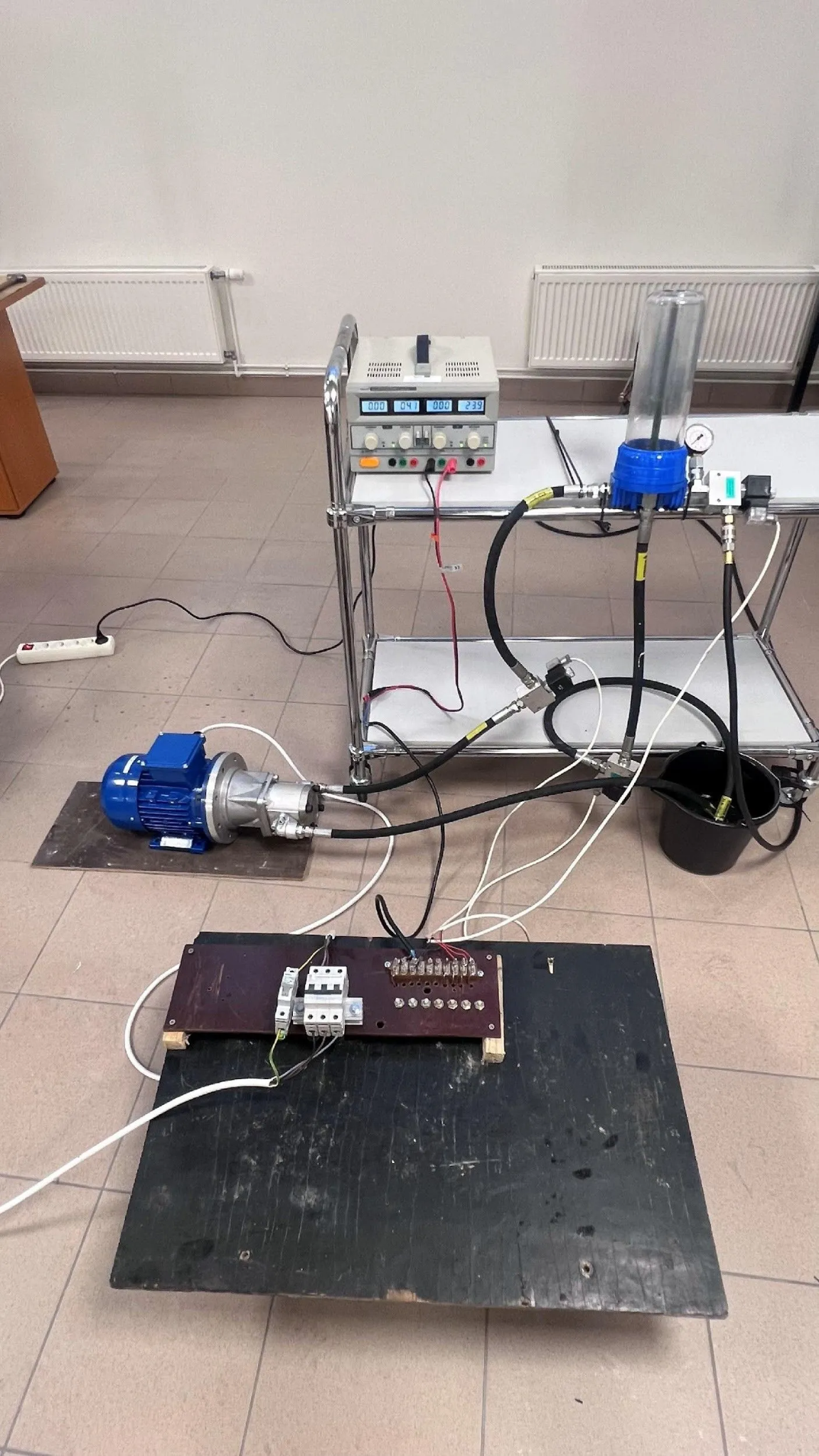

The project was launched to address industry needs and specific challenges in the field of hydrogen compression. The project started with the development of hydraulic compression technology and the objective of reaching Technology readiness level 5 (TRL). This was fully achieved during the duration of the project. The system and components of the technology (hydraulic compression process, control system, required working fluids, compression chamber geometry) were tested under laboratory conditions and in the appropriate environment (hydrogen atmosphere).

In addition, the research allowed us to develop a new compression chamber geometry and have it validated in the laboratory. The second technological solution has reached TRL 4.

The project took a big step forward in making the technology more practical and useful. It also opened up the possibility to work with industry on many new opportunities. The project focused on solving practical problems and looked at the whole process, thus becoming a key factor in taking hydrogen forward as an environmentally friendly energy source.

The originality and significance of the project results are confirmed by 2 Latvian patents and a European patent Office. The scientific material has been presented in three articles and two conferences.

During the project, we have also submitted a number of project applications for other projects related to renewable energy topics, which will help us to continue our energy related research. In addition, we plan to submit an application for a commercialised project to the Investment and Development Agency of Latvia in the near future. The patents obtained within the project attracted the interest of the international corporation Atawey, one of the leaders in the hydrogen industry. In November 2023, an auction took place in which Atawey agreed to acquire the patents. This action should foster closer cooperation between the project team and industry.

The total approved project costs amounted to EUR 539 577.35 and were financed from the following financial sources: the European Regional Development Fund - EUR 444 018.20, the government budget - EUR 55090.84, the Ventspils University of Applied Sciences, "LATVO," the State Scientific Institute - derived public person “Institute of Physical Energetics”, the foundation “Ventspils University of Applied Sciences Development Fund” in the amount of EUR 40 468.31.

The project duration was 31 months (01.05.2021 - 30.11.2023).

Information compiled by:

Scientific Supervisor of the Project: Dr.sc.ing. Valerijs Bezrukovs, Senior Researcher at VIRAC;

Project Administrative Manager Ieva Rozenberga;

Lead participant of the project Vladislavs Bezrukovs.

A diagram for the supply, storage and preparation of high-pressure hydrogen for use in gas stations.

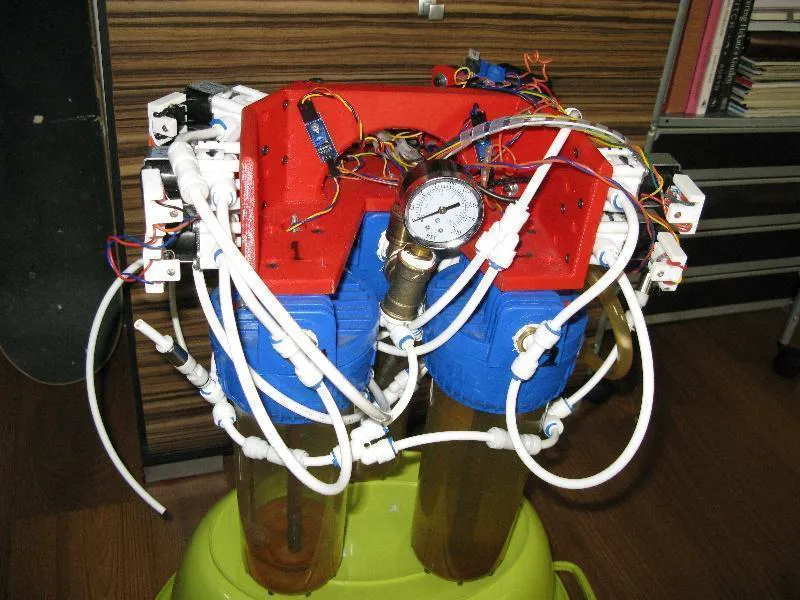

Hydraulic hydrogen compression system for gas filling stations using flow meters and additional pressure boosting tanks.

Compression chambers and fluid flow patterns.

Visualisation of the network structure used in the turbine flow sensor simulation model.

Model of a liquid type compressor.

Control system with power relays

Laboratory prototype of a hydrogen compression chamber with orthogonal working fluid injection, increased heat dissipation and reduced foaming.

Share on other platforms

Other news